Why does the washing machine jump during spin? How to eliminate the vibration of the washing machine during the spin cycle

Automatic washing machines have helped modern people love the time-consuming laundry and learn how to enjoy this process. Thanks to the invaluable invention, you can watch a movie, talk on the phone and even sleep during washing. Only one thing can interfere with a pleasant rest - if the washing machine jumps and creates an annoying rumble for the whole house. It is possible and necessary to deal with an unpleasant phenomenon, and the fight should begin by identifying the cause of excessive jumps.

During the spin cycle, the drum rotates at a frantic speed, which cannot but provoke a natural vibration of the technique. Manufacturers are trying their best to reduce the “shaking”, so that with a clear conscience they hang the label “silent operation” on their products. In order not to break the silence in the house, it is recommended to carefully look at the typewriter before purchase.

The narrower the washing machine, the more difficult it is to stay in one place

Narrow cars are most prone to leaps. In these models, the supporting area is much smaller than that of bulky competitors, hence the weak stability and "running" through the bathroom. A narrow drum is another drawback of a compact helper, linen in a small space is distributed worse, which leads to an imbalance and frightening movements.

Practice shows that models with metal tanks cause more problems, while machines with plastic tanks are quieter and more stable during spin cycle. Some modern manufacturers have found a way to separate the tank from the hull, thereby reducing vibration and noise.

What problems are the “jumps" of the new machine signaling?

If increased activity is seen in newly acquired equipment, then it makes sense to check the presence of transportation bolts that fix the tank of the machine during transportation. Very often, after connecting the unit, these fasteners are forgotten to remove, resulting in a “dancing” machine and premature wear of the main components. The mounting bolts are located on the back cover and are easy to remove. It is important not to lose these parts - they will come in handy when moving or selling equipment.

This is how transport bolts look

The second reason is the improper installation of new household appliances. Washer must be installed on a flat and solid surface with a level - the housing must in no case be rocked or staggered. Also, gliding on a smooth floor is not allowed, “figure skating” can be prevented with the help of special anti-slip nozzles for legs or a rubber mat.

The most harmless reason for strong bouncing machines - improperly loaded laundry. Frightening shaking can occur as a result of overload or uneven distribution of things. In this case, experts recommend stopping the program, pulling things out and splitting the contents into two parts or disassembling a wad of tangled laundry.

Do not neglect the correct choice of the washing program, manufacturers are not in vain spending money on the development of electronics - an inappropriate mode, as well as overloading or underloading of linen often lead to the fact that after oscillations the machine is out of place.

Anti-vibration stands prevent slipping

Sometimes small objects fall between the tank and the drum, which create an imbalance and interfere with the normal operation of the equipment. Practice shows that most often the culprit of the “horse racing” is a metal bone from a bra, and pins and coins divide the second place.

Unfortunately, the cause of the “jumps” may be a factory marriage, so you need to be prepared for the fact that you will have to part with the machine for the duration of the repair or replacement.

Important! Equipment that has not yet expired can not be disassembled on its own.

Common breakdowns of experienced cars

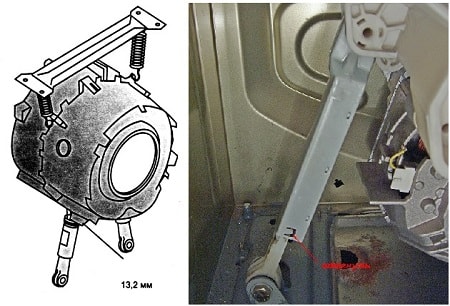

To damp natural vibrations during the spin process, elements are installed inside the casing to prevent oscillations: shock absorbers, springs or dampers. These pendants wear out over time and cease to fulfill their tasks, as a result of which the tank is skewed, leading to a collision of parts. To restore the washing machine to its former stability, new mechanisms are installed by removing the back or top cover of the machine.

It is better to entrust the replacement of shock absorbers and bearings to professionals.

Destruction and wear of one of the two axial bearings is the second common problem leading to jumping. This failure can be determined by the characteristic grinding and free lateral movement of the drum. For diagnostics, you can scroll the drum at a time when the machine is not loaded with linen, if at the same time extraneous sounds are heard - it's time to sound the alarm.

Important! Operation of equipment with a defective bearing may lead to even more serious breakdowns and the final failure of the unit.

A counterweight is another important detail that provides damping. It is a heavy block made of concrete or cast iron. Weighting agents are located in the upper and lower parts of the machine body and are attached directly to the tank. Most often, the problem is found in the counterweight mounts - over time, they become loose and require adjustment or replacement. Concrete balancing stones tend to crumble and become worthless in order to return the equipment to working capacity, it is enough to replace the worn part.

The counterweight dampens vibrations and holds the unit in place

A malfunction of the electric motor is one of the most unpleasant breakdowns that create all the conditions for the “jumping” of the machine. The most harmless reason is the unreliably fixed engine that is eliminated quickly and without unnecessary expenses. In other cases, it may be necessary to completely replace or repair a critical part. By the way, the electric motor often becomes unusable from excessive vibrations caused by improper operation - everything is interconnected in multifunctional technology.

Do not forget that the washing machine is complicated appliances electronically controlled and fine-tuned. Those who have never encountered a device of technically sophisticated devices are advised not to take risks, and when the first warning signs of abnormal jumps appear, call the wizard. Procrastination threatens not only the breakdown of an expensive thing, but also the flooding of the apartment - the “dancing” unit may disconnect from the water supply system and then financial repairs will have to include not only its own, but also the neighboring apartments.

Video: DIY washing machine repair

And so, after the next hard working day, my patience snapped, and I got up to talk "heart to heart". The neighbor opened the door, but the vile sound continued to sound in his apartment. Now it seemed that the chipper was working. Without further ado, I proceeded to the bathroom, and there his wife was riding a galloping washer. When I laughed (and it lasted about 15 minutes), I explained to them that strong vibration during the spinning of the washing machine is abnormal and this condition requires correction. I suggest that you consider this problem in more detail.

What is this fraught with

First of all, I asked how long their washing machine “jumps”. It turned out from the date of purchase, that is, three years. When asked why they didn’t solve the problem, my neighbor raised his eyebrows in surprise - isn’t the washing machine supposed to vibrate? Of course, it should be, but not so much as to jump to the corridor.

After examining the unit, I realized that these “leaps” did not go away for free.

- I found a loose drum - coupled with a “trembling" their apparatus suffered frequent leaks.

- The corners down from the bottom of the casing - it turns out that the washing machine vibrates so much that it even tipped over a couple of times “on its back” during the spin cycle.

- The loose springs that strengthen the tank. One fell out like that when I turned the typewriter over.

In addition, I sincerely did not understand how you can tolerate the fact that the washer is so noisy and do not even ask a master for advice. I generally resent when they are so neglectful of technology. But my first task was still to help, and not to read notations. Therefore, I patiently explained that a large vibration during the spin cycle is dangerous for the washer, and below I have written for you the reasons why it can occur. To help avoid costly repairs in the future.

Why did the machine make races

Typically, the washing machine is tested in the first days after purchase: how it works, whether there are problems, whether extraneous noise is heard during the spin cycle. At the initial stage, identifying the cause and eliminating it is much easier.

So why is there a strong vibration:

This information will tell you how to reduce the vibration of a newly commissioned machine.

But what to do if the level of noise in the washing machine that you have been using for a year is going off scale and there were no complaints before that.

Here's what could happen:

While I was telling all this to a neighbor, his wife sat on a desperately howling washing-machine all the time and also listened carefully. And then she asked how to eliminate this trouble that has plagued them for almost three years. I already realized that I would not leave soon and, rolling up my sleeves and pushing my neighbor to the side, I began a more detailed inspection of the unit.

Remedies

To understand how to remove excessive vibration, you must first determine its root cause. In the case of my neighbors, I found several of them: a clumsy floor, and worn shock absorbers, and, as I already said, a fallen spring. Since the case was running, I advised you to call the wizard.

- Before buying, prepare a place for the washing machine, making sure that the floor is even. As I wrote above, the best coating is tile.

- After delivery, ask the master or remove the fixing fixtures from the drum yourself - they are needed so that it does not rotate during the trip. But if you forget to remove them, then there will be problems in the form of noise and vibration.

- During installation, adjust the level using shock absorbers - if there is a slope, compensate for it with a thicker layer of rubber.

If the problem catches up with you after a few months:

These are all minor nuances, the elimination of which will not take much time and effort. There are only two serious reasons for concern - rusted bearings and a damaged counterweight. Both cases require professional replacement of broken parts. What I highly recommend doing immediately so as not to aggravate the situation.

I wish you all a trouble-free technique and see you soon!

Need information on the spin classes of a washing machine?

Thanks for attention! Sincerely, Rostislav Kuzmin.

You do not know what happened to your washing machine, because of which it began to jump, vibrate violently and make uncharacteristic sounds? Perhaps she moved off her legs or became wrong. But also strong vibration can indicate a more serious problem that needs immediate repair. So it can cause noise. We’ll try to figure it out before this problem gets worse.

Why does the washing machine start to spin when spinning

There are a lot of reasons why the washing machine jumps and makes stronger noises. Let's look at what kind of malfunctions can cause strong vibration of the washing machine:

- When washing small objects can get between the drum and the tank, for example, sometimes we can wash things with coins, paper clips, bedding with pins or small buttons and fasteners get caught.

- If the transport bolts were not unscrewed during installation.

- Incorrectly distributed laundry in the drum of the machine (found in older models of washing machines).

- If your motor is broken.

- The washing machine is not correctly installed on the supports.

- Check if bearings are out of order.

- Defective or heavily worn springs and shock absorbers.

- Another reason may be a weakening of the mount or deformation of the counterweight.

Troubleshooting

The problems are manifold, and it’s very difficult to immediately find out what could cause strong vibrations. Therefore, it will be more rational to exclude, at first the simplest options, the washing machine rumbles and shakes. What to do to find out the simple reasons why the washing machine jumps during the spin cycle:

- Take a close look to see if the laundry is wrapped in a knot; it often happens that small items of clothing are clogged in a duvet cover or sweaters.

- It should be checked whether the maximum amount of laundry in the machine exceeds. For each washing mode and machine models, different allowable indicators are possible.

- Noise can occur when things occupy more than 2/3 of the volume of the drum.

In such cases, some washing machines are equipped with a special sensor that displays errors of the type: UE or UB on the display.

How to install a washing machine so that it does not jump?

Strong vibrations can often be caused by incorrect installation or typical errors, especially when the equipment is not installed by professionals or installation is done independently. The most typical mistake is that they simply forget to remove or install the device unevenly or put it on a slippery surface (tile), which causes staggering and, as a result, a lot of noise.

Why the washing machine jumps when installed incorrectly and what to do:

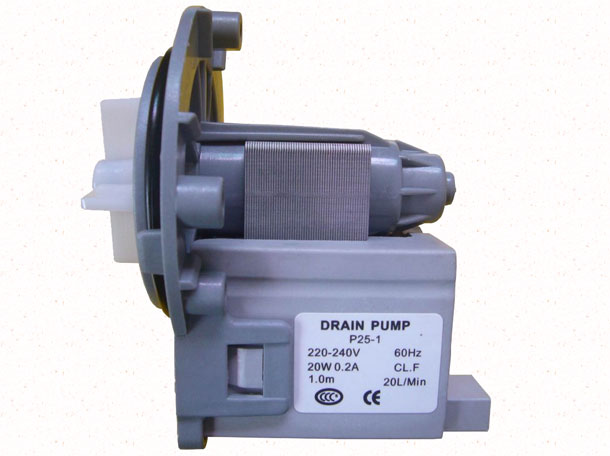

- The first thing you need to remove the transportation fasteners. They are installed to fix the drum so that it is not damaged during transportation. If they are not removed, the drum will spin, but its wear will be greatly increased, and the operation of the device will be accompanied by strong vibration and bouncing.

- Carefully watch that the equipment is installed strictly according to the level. To do this, you can twist the legs and adjust their height. During the spin, the machine enters into resonance and can even move around the room, therefore it is not recommended to leave the faulty equipment in working condition without supervision.

- After the installation is completed, check if the device is staggering. Any, even the slightest stagger can lead to bouncing. If washing machine Since the machine is staggering, it will have to be aligned.

Even if the equipment will be installed by professionals, it is better to independently check these nuances to make sure that everything is in order. Be sure to test the work after installation. Such actions will help you save time on the subsequent recall of the installers, so that they fix the problem and not wonder what to do so that the machine does not make frightening sounds.

Defective shock absorbers

It is necessary to inspect the shock absorbers, which serve to mitigate the blows during the movement of the drum, reduce loads and dampen vibrations. If the device vibrates violently or jumps, then perhaps the shock absorbers will have to be replaced. Shock absorbers are mounted together with spring mechanisms, but if only shock absorbers are worn out - they can be replaced separately, if the springs are out of order, then you will have to change everything all at once. Over time, the shock absorbers wear out and cannot be repaired - immediately change. Depreciation can be uneven, but if only one is faulty, both shock absorbers must be replaced so that there is a balanced load distribution.

Look, maybe small things are stuck under the drum. If they are, then you have to get them. For example, a bone from a bra or a clip can be easily taken out, if you pick it up with something, you can do something like a hook, which will be convenient to pull out small parts. If you get stuck in smaller parts that you can’t get out, you will have to disassemble the washing machine. To do this, remove the heating element, drum and some other parts. If you have never disassembled washing machines, then it is better to call a wizard who will do this as quickly as possible, which will save you a decent time, but most importantly, it is safe for technology.

Problems with securing counterweights

If the washing machine began to vibrate and jump strongly, you need to check the operation of the counterweight. We open the lid in the upper part of the device, for this you may need tools, it will be enough to use keys, a screwdriver and pliers. We look at the state of the counterweight, it is a weighting agent, which is made of different materials. Such parts are installed at the top and bottom of the washing machine. They can be made of concrete, cast iron, or other heavy material.

What to do next:

- We look at the mounts, if they loose, then they will need to be tightened.

- If you can’t tighten the fasteners, you will have to purchase and install new ones.

- If the weighting agent itself is deformed, one cannot do without replacing it with the same one.

One of the reasons a machine can jump is a bearing breakdown. The replacement process is technically complicated, so it’s better to call a master who can do this job in a good quality manner. If you still want to do this yourself, you will need more information about this process, so you can read the corresponding article about it.

Bearing problem

Faults associated with bearing failure are far from a rare occurrence. The main reasons for the breakdown of this part are due to the fact that the metal from which the elements are made collapses over time due to exposure to water. When the bearings begin to collapse, the operation of the apparatus will first be accompanied by increased vibration and noise, and then the drum may jam completely.

When the bearing is just starting to break, identifying problems is quite difficult. Usually, professionals can tell about the wear of a part by sound, but for this you need to have experience and knowledge. But when the bearing is already badly damaged, you can move the drum. When he moves in different directions, it says that it is time to call the master to.

What can we talk about in the end? It turns out that the washing machine is a complex system that needs professional help to fix technical problems and you should contact qualified specialists with experience and knowledge to quickly and efficiently fix the problem.

Is it normal if the washer jumps?

Often during washing during the spin cycle, the washing machine jumps and vibrates violently. If it is new, and washing is the first, then it was incorrectly installed, or there is a factory defect. If the machine has been used repeatedly, then the cause of the vibration is a breakdown. Consider the action plan for both options in more detail.

When vibration of a new machine follows:

Remove three or four transport bolts and retaining elements on the back cover of the unit if they were not removed during installation.

Bolts are necessary for fixing the tank during transportation, so as not to damage the machine. Without bolts, the vibration of the machine must be damped by the shock absorbers on which it is held. If the bolts are removed and there is a suspicion of a factory defect, you should call the wizard from the repair service to determine the cause.

Check floor level for skew.

When spinning, the machine operates at the highest drum speeds, so the surface of the floor should be perfectly flat. If the floor is concrete or the machine is on the tile, then to reduce vibration and level its level, you should tighten (adjust) the wheels on the legs. If the floors are wooden and sag, then under the machine you need to put a rubber mat or even two.

If the machine moves on a smooth and slippery tile, then a rug can also come in handy. You can attach special stickers to the legs to prevent slipping or construction tape, which has an adhesive surface on both sides.

Check load of laundry.

One of the reasons: the weight of the laundry exceeds the maximum permissible value for the selected washing mode.

One of the reasons: the weight of the laundry exceeds the maximum permissible value for the selected washing mode. If there is not enough laundry in the drum or, on the contrary, too much, it will not be distributed correctly, in a large lump, which leads to strong vibration, shaking and “bouncing” of the machine, and as a result, to weakening of fixing bolts, wear of component parts of the unit. In this case you need to stop the machine and put the laundry in order: straighten and distribute more correctly on the drum. Then the washing can be continued.

When the drum is overloaded with laundry, it is poorly removable due to the absence of friction of things, poor rinsing with clean water and spinning will be poorly performed.

Check the integrity of the counterweight and its mounting.

At the place of water collection (in which the washing takes place), a counterweight of a certain severity is attached to the tank at the factory for balance from concrete, plastic or cast iron. During operation, the counterweight may crack and crumble, especially from concrete, or weaken its fastening. Then the load will not be able to dampen the vibration, but will only strengthen it. Fix fixing bolts or call a wizard to replace the counterweight. It may be necessary to replace the fixing bolts themselves.

Check for shock absorbers or dampers.

To check if there are any foreign objects between the tank and the drum, it is enough to shine a flashlight inside the drum.

To check if there are any foreign objects between the tank and the drum, it is enough to shine a flashlight inside the drum. In the new car, shock absorbers can be defective, in the "age" - they can dry, wear out and be damaged. Then you need to wait for other breakdowns. After removing the transport bolts, the machine hangs on shock absorbers. At the same time, work is softened and noise is eliminated. With frequent loading of the unit, parts fail and must be changed.

To see the shock absorbers and diagnose them, you need to unfasten the wall in the car in front or behind. When the shock absorbers fail, the force required by the technology for assembling the machines will not be provided. It is necessary to disconnect the mount and check the force by pressing on them by hand. If the depreciation function is lost, the spring travel will be easy, and the vibration of the machine will be increased. The device is fixed with plastic sleeves or bolts: from one end to the bottom of the case, from the other to the tank.

When dismantling, unscrew the bolts or remove the plastic bushings, previously pressing the latches. New shock absorbers are installed by repeating all the steps in the reverse order. If it is impossible to do this work yourself, you should call the master to repair the machines.

Dampers do not move independently, but there are plates in it that can move or tubes with a rigid mount with a tank. If the plastic covers, fitting plates or tubes coming from the tank break, the dampers fail. The cause of the breakdown is the vibration of the tank, since the details of the U-shaped dampers receive the same shake due to the tight connection to its body.

Video review of the reasons:

To change the plastic covers you need:

unscrew the screws;

disconnect the damper from the unit body;

remove the damper from the mounts;

remove and replace damaged plates with new ones. To do this: unclench metal rods. One is taken away with the hand, the second is fixed with the foot, the covers are removed. With the other hand, insert new plates between the rods and gradually reduce the tension to bring them back.

If the owner of the machine finds it difficult to perform such work, you need to contact the nearest repair service.

Check bearing wear.

Bearing wear occurs when moisture gets in: it rusts and breaks. Therefore, at first the machine can make a rattle of iron, in the future there is a free lateral stroke of the drum shaft, which leads to increased vibration during the spin cycle. Such damage should not be ignored..

You should not use the machine further without replacing the bearings, since larger breakdowns of the units of the unit can occur, the replacement and repair of which will be very expensive. Replacing bearings is a labor-intensive process that requires experience and knowledge, so you need to use the services of repair service specialists.

When installing washing machines, do not neglect the rubber pads under the legs.

When installing washing machines, do not neglect the rubber pads under the legs. If you follow the safety rules, instructions and recommendations of specialists, treat the equipment with care, it will work properly for many years. If the washing machine begins to bounce, move, vibrate violently during the spin cycle, you should deal with small causes and eliminate them yourself.

A washing machine jumps - what to do? Strong vibration of the washing machine, when it shakes during the spin cycle, is a signal of malfunction or incorrect installation. There are many reasons for this.

Manifestations:

- the washing machine vibrates violently during the spin cycle;

- the washing machine jumps and shifts during spinning.

Why is the washing machine jumping?

Causes:

- Unstable support on the basis (floor).

- Damage to shock absorbers.

- Loosening the counterweight or destroying the counterweight.

- The transport device is not removed.

- Imbalance of linen.

- Worn bearings.

Repairs:

Disconnect from electricity. Unplug the washing machine.

Stability on the floor. First of all, you need to check the stability of the washing machine, it should be firmly on the base. The floor on which the machine is installed must be solid and monolithic, if the floor is plank and bends, vibrations will occur.

Then check the legs, they are usually regulated, and sometimes, during operation, unscrew and this leads to instability. To avoid this, you need to fix each leg with a lock nut.

Shock absorbers or dampers. Check shock absorber wear. To do this, access them by disconnecting the back cover or front wall of the washing machine. On washing machines, shock absorbers or dampers are installed. Shock absorbers have a certain "move". They are designed for a certain force, which corresponds to the model of the washing machine on which they are installed.

Defective shock absorbers do not provide the required force. This can be checked by disconnecting one of the ends of the shock absorber mounting and checking it manually. The defective shock absorber has an easy “stroke”, which leads to increased vibration at the spin. Shock absorbers are fastened with bolts or plastic bushings on latches, one end to the bottom of the machine body, the other to the tank. To dismantle them, you need to unscrew the nuts and pull out the bolts or pull out the plastic bushings after drowning the latches, then insert new shock absorbers and repeat the reverse operation.

Dampers do not have their own “stroke”, but provide it due to the movement of the tube or plate, rigidly attached to the tank, in the plates of the damper. Damage malfunctions are most often expressed in the breakdown of plastic plates that fit tubes or plates extending from the tank. These elements are one with the tank and transmit all vibrations to the plastic plates. The plates, in turn, are tightly pressed to the tubes or plates using U-shaped metal rods that are attached to the tank body of the washing machine.

To replace the plastic covers, you need to disconnect the damper, unscrewing several screws from the machine body and removing the damper from the mount. Next, remove the cracked or broken covers and put new ones. To install new plates, it is necessary to unclench the U-shaped metal rods, securing one of them, for example, with the foot, and the other by hand. With the other hand, insert the plates between the rods and bring them back, loosening the tension. Installation of dampers is carried out in the reverse order, taking into account the individual characteristics of a particular model.

Attachment of counterweights. Check condition and mounting of counterweights. They are mounted on the tank of the washing machine with bolts. They are plastic and concrete. Problems usually arise with concrete, it happens that over time they crumble or crack.

Also, due to improper loading of linen and the occurrence of increased vibrations, it is possible to loosen the fixing bolts. All this leads to the fact that the washing machine jumps on the spin, shakes and there is accelerated wear of other components of the washing machine.

Shipping devices. There are times when, when installing the new washing machine yourself, the transportation device is forgotten to be removed. It fixes the drum inside the washing machine so that it is not damaged during transportation. During installation, the transport device must be removed, otherwise a rigidly fixed drum will vibrate violently, which will lead to rapid wear of many components. Therefore, if all of the above reasons have not been confirmed, we check the transportation bolts.

The importance of proper loading. Increased vibration and shaking are sometimes caused by an imbalance in the laundry caused by its uneven distribution before spinning. This sometimes happens if loading laundry before washing is done carelessly, “lumpy” or due to overload. In this case, you need to stop the spin, decompose each piece of linen, so that in the machine it can be distributed before the spin. As for the overload of linen, in this case it is also washed worse because it does not have the ability to rub against each other, but rolls around with a ball inside the drum.

Bearing wear. Excessive bearing wear can cause increased shaking of the washing machine. First, worn bearings begin to make noise, and then gradually collapse, this leads to free lateral movement of the shaft with the drum and strong vibration at the spin. Further operation of such a machine will lead to a significant increase in the cost of repairs.